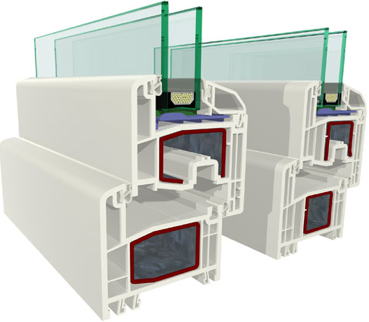

The primary defining factor in vinyl window profiles is the number and arrangement of the chambers inside the profile. The figure that matters here is the lowest number of chambers in the direction of heat flow through the profile.

Due to their relatively bad insulation values, profiles with only one chamber are no longer available. They cannot hope to meet the needs of today’s market or legal minimum requirements.

Two chamber profiles have an outer insulating chamber, and an inner chamber to hold the steel stiffener. With the outer chamber, these profiles are an improvement over the one-chamber profile (typical U-values of 1.8 to 2.1 W/m²K).

Three chamber profiles also have an antechamber on the indoor side, for even more improvement to the thermal insulation. The U-value for these profiles is often between 1.5 and 1.9 W/m²K. The construction depth for profiles with this design lies at 62millimeters.

Today, however, most profiles have four or more chamber. As a general rule of thumb, the more chambers in a profile’s design, the better the insulation factor. Profiles are available with four, five, six or seven chambers and with construction depths of 74mm to 83mm. These modern designs can reach U-values as low as 0.98W/m²K.

-1222.png )